As the European Union pushes its Green Deal, the construction sector, which accounts for around 9% of the EU’s GDP, is undergoing a massive transformation. Companies across the Member States need to adapt to strict environmental regulations and circular economy principles.

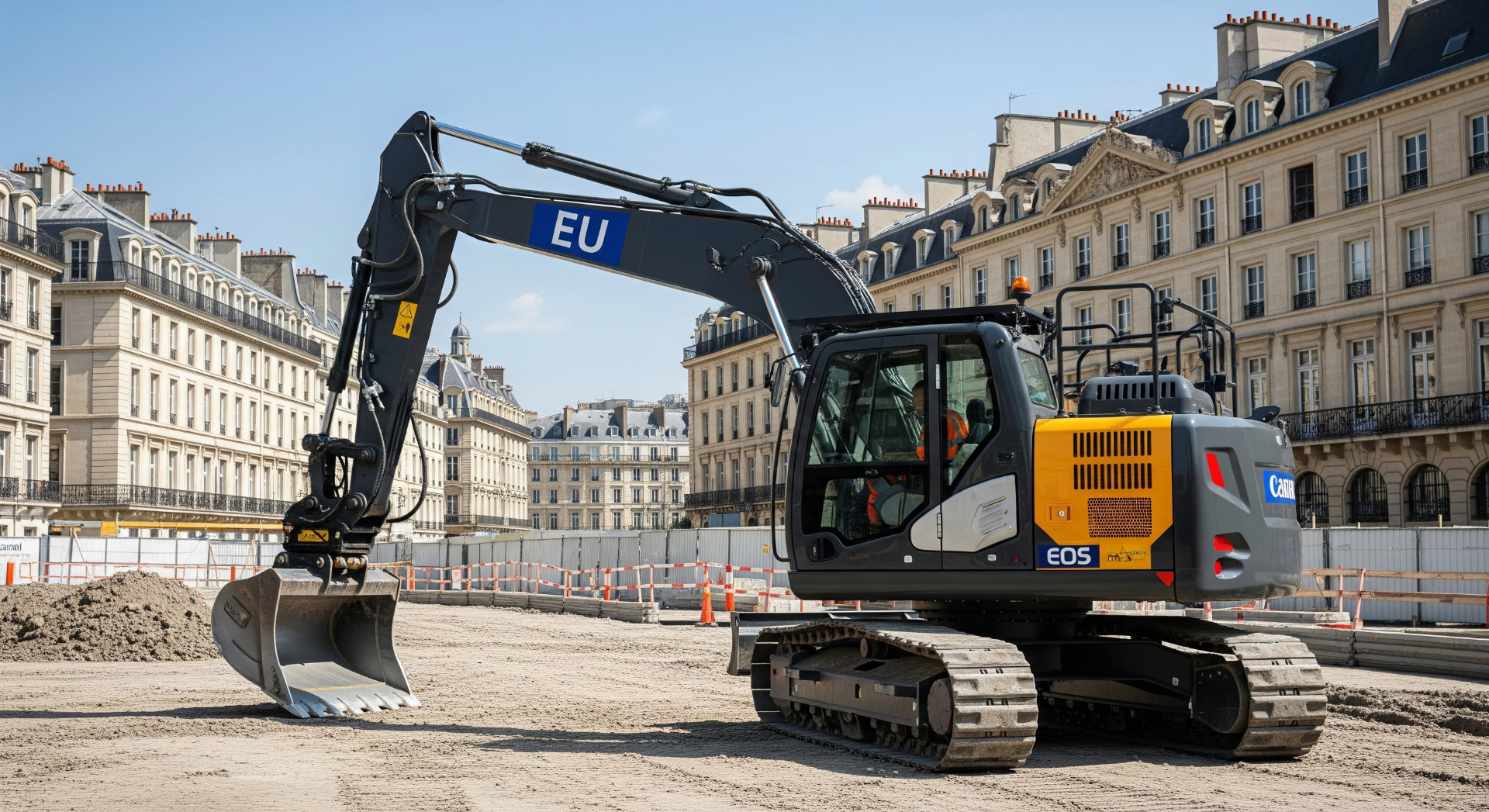

In this new landscape, the adoption of specific, efficiency-driving technologies is a must. For companies using heavy machinery, one of the most impactful innovations is the use of advanced excavator track pads, which directly support compliance and sustainability goals.

Regulatory Compliance and Urban Development

In Europe’s historic and densely populated city centres, construction projects are governed by a complex web of regulations on noise emissions, vibration limits and protection of public infrastructure. Using traditional steel-tracked excavators on paved surfaces is a direct conflict with these rules, risking financial penalties and project delays.

Modern excavator track pads, which can be bolted or clipped onto a standard steel undercarriage, is the solution. By replacing the damaging steel-on-pavement contact with a high-durability rubber interface, construction companies can achieve several key compliance goals:

- Noise Reduction: Significantly reduce operational noise to comply with municipal ordinances, work in residential areas and during restricted hours.

- Infrastructure Protection: Prevent costly damage to roads, pavements and historical surfaces, reduce liability and protect public assets.

- Safety: Provide better traction on hard, often wet surfaces, reduce the risk of slippage and improve worksite safety, a core principle of EU workplace regulations.

The Circular Economy and Lifecycle Management

The EU’s Circular Economy Action Plan puts a big emphasis on reducing waste and maximising the lifecycle of materials. This principle applies to the procurement of construction components. A low-cost, low-quality track pad that fails prematurely generates unnecessary waste and operational disruption.

Forward-thinking European companies are therefore moving towards a Total Cost of Ownership (TCO) model for procurement. This approach looks at the entire lifecycle of a component, from initial cost to maintenance, lifespan and end-of-life disposal. Premium track pads, often made in the EU or by companies that adhere to high production standards, offer a better TCO.

Their advanced rubber compounds and robust construction means a longer service life, less replacement and associated waste. And as the industry evolves, the opportunity for remanufacturing and recycling these components will grow. The steel cores can be refurbished and bonded with new rubber, creating a closed-loop system that fits perfectly with the EU’s circular economy and gives companies a more sustainable and cost-effective supply chain.

Economic Strategy for Competitive Advantage

In a competitive EU market, operational efficiency is a key differentiator. The flexibility of rubber track pads allows companies, especially SMEs that make up the majority of the sector, to do more with less. One excavator can be used across more projects, from greenfield sites to urban renewal, maximise the return on a big capital investment.

This flexibility reduces the need for special rental equipment and streamlines project logistics, resulting in faster completion times and higher profitability.

As the EU funds its “Renovation Wave” to improve the energy efficiency of buildings, the ability to work efficiently and cleanly in established urban areas will be key for any company looking to win public tenders.

In summary, for companies operating in the EU’s construction sector, the adoption of technologies like advanced excavator track pads is a no-brainer. It’s a response to the regulatory pressures of the Green Deal, a practical step to circular economy and a smart business decision to be more competitive in a tough market.